Glass Fiber

FRP EASY range for open mould process

Easygun

PROPERTIES

easygun® is made out of continuous E-glass strands, gathered without mechanical twist. Each strand is made up of numerous glass filaments that are bonded together with a polyester & vinylester compatible size.

SPECIFICATIONS

| Reference | Tex | Filaments diameter | Sizing | Loss of ignition (%) | Stiffness | Moisture content (%) |

|---|---|---|---|---|---|---|

| easygun® | 2400 | 11 µm | Silane | 1,1 (+/- 0,15) | Medium | <0,05 |

PACKAGING

| Reference | weight per cheese | Cheese per pallet | Net weight per pallet | 20′ container | |

|---|---|---|---|---|---|

| Pallet | Net weight | ||||

| easygun® | 18 | 48 | 864 | 20 | 17,280 |

STORAGE

easygun®should be stored dry in its original packaging. Storage temperature : max. 35 °C – Relative moisture : < 70 %.

Easymat Emulsion

- Excellent compatibility with all types of polyester resins

- Easy handling, good bubble releasing, very good «feel»

- Good conformability

- High strength of FRP products

A medium bulk chopped strand mat, manufactured from «E» glass fibres, coated with a silane base size. The glass filaments -12 µm and 30 tex- are chopped to approximately 50 mm and are distributed to give minimum orientation of the glass fibres. The chopped strands are bound together with an emulsion binder to form a porous mat that is white in color. easymat® is specially suited for parts requiring a good surface finish.

easymat® should be stored dry in its original packaging. Storage temperature : max. 35 °C – Relative moisture : < 70 %

Easycore

- Easycore® is a low density, non woven laminatable core material containing thermoplastic hollow microspheres

MAIN FEATURES IN THE LAMINATE

- Low density

- High flexural strength and improvement of impact strength

- Low interlaminar stress

- Reduction of shrinking effects

- Reduction of print-through effects

TYPICAL PROPERTIES

5 standard grades.

| Unit | E-1000 | E-2000 | E-3000 | E-4000 | E-5000 | |

|---|---|---|---|---|---|---|

| Thickness (dry) | mm | 1 – 1.4 | 1.8 – 2.3 | 2.7 – 3.3 | 3.6 – 4.4 | 4.5 – 5.4 |

| Weight | g/m² | 65 | 80 | 95 | 130 | 140 |

| Width | cm | 100 | 100 | 100 | 100 | 100 |

| Roll length | m | 100 | 70 | 50 | 40 | 35 |

| Roll diameter | cm | 45 | 45 | 45 | 45 | 45 |

Special widths and roll lengths on demand

PACKAGING

Each individual roll is wrapped with translucent polyethylene film.

EASYVEIL

Direct Roving:

Direct Roving is an untwisted, single end roving, supplied as a tubeless package, for use in continuous process operations, such as weaving, pultrusion and filament winding. The sizing is specifically designed for fast wet out, good processing and handling characteristics as well as

excellent adhesion with most Polyester, Vinyl Ester and Epoxy resins.

TGI Direct roving

PROPERTIES

- Very low fuzz

- Fast wet out

- Good processing characteristics

- Low catenary

- Good handling characteristics

- High mechanical properties

Assembled Roving:

Spray up Roving

Centrifugal casting roving

SMC roving

Panel Roving

Chopped Strands Mat

Chopped Strands Mat - Emulsion Bond

Easeymat E

Easymat P

Single YARN

Fiberglass yarn are drawn from molten E-glass. Fine filaments are gathered up and wound as a cake on a collector at a speed upto 4,000m/min. Prior to be wound, filaments are coated with special sizing. Then, strands are transferred from cake to a bobbin by a twister. Our Fiberglass yarn are suitable for inductrial applications.

TGI Yarn

| Style | Tex (g/1000m) | Solids (%) | Moisture (%) | TPC(turns) | Tensile Strength (gf/tex) | Broken Filament | ||

|---|---|---|---|---|---|---|---|---|

| EC9 136 | ECG 37 | 134.00±3.00 | 1.15±0.20 | <0.20 | 0.70±0.20 | 28±8 | mini 48 | maxi 10 |

| EC9 75 | ECG 67 | 72.00±1.75 | 1.10±0.20 | <0.20 | 0.70±0.20 | 28±8 | mini 48 | maxi 10 |

| EC9 68 | ECG 75 | 68.30±1.75 | 1.10±0.20 | <0.20 | 0.70±0.20 | 28±8 | mini 48 | maxi 5 |

| EC9 34 | ECG 150 | 33.10±1.00 | 1.20±0.20 | <0.20 | 0.70±0.20 | 28±8 | mini 48 | maxi 5 |

| EC7 45 | ECE 110 | 45.00±1.25 | 1.25±0.20 | <0.20 | 0.70±0.20 | 28±8 | mini 50 | maxi 5 |

| EC7 22 | ECE 225 | 22.30±0.75 | 1.55±0.30 | <0.20 | 1.00±0.20 | 40±8 | mini 50 | maxi 5 |

| EC6 34 | ECDE 150 | 33.10±1.00 | 1.30±0.20 | <0.20 | 1.00±0.20 | 40±8 | mini 55 | maxi 5 |

| EC6 16 | ECDE 300 | 16.60±0.50 | 1.80±0.30 | <0.20 | 1.00±0.20 | 40±8 | mini 55 | maxi 5 |

| EC5 11 | ECD 450 | 11.10±0.50 | 1.85±0.30 | <0.20 | 1.00±0.20 | 40±8 | mini 60 | maxi 5 |

| EC5 5.5 | ECD 900 | 5.10±0.50 | 1.85±0.30 | <0.20 | 1.00±0.20 | 40±8 | mini 60 | maxi 5 |

GYNMT Yarn

| Style | Tex (g/1000m) | Solids (%) | Moisture (%) | TPC (turns) | Tensile Strength (gf/tex) | Length (m/bobbin) | ||

|---|---|---|---|---|---|---|---|---|

| ISO1889 | ISO1887 | ISO3344 | ISO1890 | ISO3341 | ||||

| EC9 136 | ECG 37 | 136.00±4.00 | 1.00±0.20 | <0.15 | 0.70±0.10 | 28±4 | >50 | 62,600 |

| EC9 68 | ECG 75 | 68.70±1.70 | 1.00±0.20 | <0.20 | 0.70±0.10 | 28±4 | >45 | 125000 |

| EC9 34 | ECG 150 | 34.00±1.80 | 1.10±0.15 | <0.10 | 0.70±0.10 | 28±4 | >50 | 108400 |

| EC7 45 | ECE 110 | 45.00±1.25 | 1.25±0.20 | <0.20 | 0.70±0.10 | 28±4 | mini 50 | 161500 |

| EC7 22 | ECE 225 | 22.50±1,10 | 1.20±0.20 | <0.15 | 0.90±0.12 | 36±5 | mini 50 | 160000 |

| EC6 68 | ECDE 75 | 68.00±2.00 | 1.10±0.15 | <0.10 | 0.70±0.10 | 28±4 | mini 50 | 54000 |

| EC5 11 | ECD 450 | 11.20±0.60 | 1.20±0.20 | <0.15 | 0.90±0.15 | 36±6 | mini 60 | 168000 |

| EC5 5.5 | ECD 900 | 5.60±0.35 | 1.20±0.20 | <0.15 | 0.90±0.15 | 36±6 | mini 60 | 203000 |

NAG Yarn

| Style | Filament diameter (µm) |

Tex (g/1000m) | TPC(turns) | Sizing system | Weight (kg) |

Solids (%) |

Yam length (m) |

Tensile strength (g/tex) |

Bobbin Type | |

|---|---|---|---|---|---|---|---|---|---|---|

| EC7-22 | ECE 225 | 7 | 22.5 | 0.8Z / Z32 | A03 | 4K | 1.1 | 161200 | 50 | 7030 |

| EC9-34 | ECE 150 | 9 | 33.7 | 0.7Z / Z28 | DP | 4K | 0.4 | 100 200 | 50 | 7030 |

| EC9-34 | ECE 150 | 9 | 33.7 | 1.0Z / Z40 | DP | 4K | 0.4 | 100 200 | 50 | 7030 |

| EC9-68 | ECE 75 | 9 | 68.8 | 0.7Z / Z28 | DP | 8K | 0.4 | 100 200 | 50 | 7040 |

| EC9-34 | ECE 150 | 9 | 33.7 | 0.7Z / Z28 | NO 5 | 4K | 1.0 | 100 200 | 65 | 7030 |

| EC9-68 | ECE 75 | 9 | 68.8 | 0.7Z / Z28 | NO 5 | 8K | 1.0 | 100 200 | 65 | 7040 |

| EC9-136 | ECE 37 | 9 | 137 | 0.7Z / Z28 | NO 5 | 8K | 1.0 | 50000 | 65 | 7040 |

| EC9-34 | ECE 150 | 9 | 33.7 | 0.8Z/ Z32 | B12 | 4K | 0.8 | 100 200 | 50 | 7030 |

| EC9-34 | ECE 150 | 9 | 33.7 | 0.8Z/ Z32 | YP | 4K | 1.1 | 100 200 | 50 | 7030 |

| EC9-68 | ECE 75 | 9 | 68.8 | 0.7z / z28 | B12 | 8K | 0.8 | 100 200 | 40 | 7040 |

| EC9-68 | ECE 75 | 9 | 68.8 | 0.7z / z28 | B12 | 10K | 0.8 | 100 200 | 40 | 7040 |

| EC9-68 | ECE 75 | 9 | 68.8 | 0.7z / z28 | YP | 8K | 1.1 | 100 200 | 40 | 7040 |

| EC9-74 | ECE 67 | 9 | 74 | 0.7z / z28 | B12 | 8K | 0.8 | 92500 | 40 | 7040 |

| EC9-136 | ECE 37 | 9 | 137 | 0.7z / z28 | B12 | 8K | 0.8 | 50000 | 40 | 7040 |

| EC9-204 | ECE 25 | 9 | 200 | 0.7z / z28 | B12 | 8K | 0.85 | 33500 | 40 | 7040 |

| EC9-272 | ECE 18 | 9 | 275 | 0.7z / z28 | B12 | 8K | 0.85 | 25000 | 40 | 7040 |

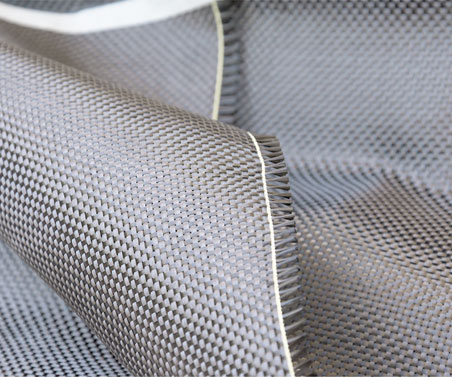

Woven Roving and Complexes

E-glass woven roving

E-glass woven roving is weaved with E-glass direct roving and a high-performance reinforcing materials, which is widely used in hand lay up and robot processes to manufacture boats, vessels, plane and automotive parts, furniture and sport facilities

Fiberglass Combo Mat

Fiberglass combo mat is made of woven roving and chopped strands randomly dispenced fibers kintted together with organic yarn, applying for hands lay up, compression molding, pultrusion or filament winding.

Speed Flow Core Mat

Core flow mat is a stratified reinforcing fiberglass mat composed by 3 layers, 2 layers of fiberglass and 1 of synthetic fibers. This reinforcing material has been specially designed for closed mold processes, as opposed to hand lay-up and spray-up open mold processes, because resin is not in direct contact with the workshop air but is processed only when the mold is tightly closed. As a result, no volatile organic compound (VOC) or styrene is released in the air.

Main applications : wind turbine blades, marine, transport.

Benefits of Vaccum infusion Process vs. Open Molding

-

-

- Drastically reduced styrene emissions

- Stronger composite laminates

- Repeatability and consistency between parts (weight and dimensional properties)

- Superior application of core materials

- Accurate bill of materials

- Lower tooling costs than other closed mold processes

-

Identification

SF 300-P180-300

| Construction | Area Weight, g/m 2 | Tolerance | Remark |

|---|---|---|---|

| Top Mat | 300 | ±10.0 | E-Glass 2400 Tex |

| Core | 180 | ±10.0 | Non-woven fabrics of PP |

| Bottom Mat | 300 | ±10.0 | E-Glass 2400 Tex |

| Stitching | 10 | ±10.0 | Polyester 108d’tex |

| Total Area Weight | 1090 | ±10.0 | |

| Stitch Gauge: 3.5 Gauge/25mm | Stitch style: tricot Stich | ||

| Stitch length: 4.5mm | Loss of Ignition: – | ||

| Moisture content: ≤.15% | Width: ±10mm | ||

Example : SF 300-P180-300

SF: CoreFlow/RTM

300: Nominal weight per square meter (g/m2) of top mat

P180 Nominal weight per square meter 180g/m2 of non-woven fabrics

300: Nominal weight per square meter (g/m2) of bottom mat

SF 450-P180-450

| Construction | Area Weight, g/m 2 | Tolerance | Remark |

|---|---|---|---|

| Top Mat | 450 | ±10.0 | E-Glass 2400 Tex |

| Core | 180 | ±10.0 | Non-woven fabrics of PP |

| Bottom Mat | 450 | ±10.0 | E-Glass 2400 Tex |

| Stitching | 10 | ±10.0 | Polyester 108d’tex |

| Total Area Weight | 1090 | ±10.0 | |

| Stitch Gauge: 3.5 Gauge/25mm | Stitch style: tricot Stich | ||

| Stitch length: 4.5mm | Loss of Ignition: – | ||

| Moisture content: ≤.15% | Width: ±10mm | ||

Example : SF 450-P180-450

SF: CoreFlow/RTM

450: Nominal weight per square meter (g/m2) of top mat

P180 Nominal weight per square meter 180g/m2 of non-woven fabrics

450: Nominal weight per square meter (g/m2) of bottom mat

SF 600-P180-600

| Construction | Area Weight, g/m 2 | Tolerance | Remark |

|---|---|---|---|

| Top Mat | 600 | ±10.0 | E-Glass 2400 Tex |

| Core | 180 | ±10.0 | Non-woven fabrics of PP |

| Bottom Mat | 600 | ±10.0 | E-Glass 2400 Tex |

| Stitching | 10 | ±10.0 | Polyester 108d’tex |

| Total Area Weight | 1390 | ±10.0 | |

| Stitch Gauge: 3.5 Gauge/25mm | Stitch style: tricot Stich | ||

| Stitch length: 4.5mm | Loss of Ignition: – | ||

| Moisture content: ≤.15% | Width: ±10mm | ||

Example : SF 600-P180-600

SF: CoreFlow/RTM

600: Nominal weight per square meter (g/m2) of top mat

P180 Nominal weight per square meter 180g/m2 of non-woven fabrics

600: Nominal weight per square meter (g/m2) of bottom mat

Others

C-GLASS SURFACE TISSUE

CONTINUOUS FILAMENT MAT (CFM)

MULTIAXIAL / KNITS

UNI DIRECTIONAL FABRICS : Please refer to our Industrial Textile Business

WET CHOP

TAIWAN GLASS IND. CORP.

PROPERTIES

- Good flow consistency

- Excellent fiber dispersion

Wet chop strands are made by chopping continuous E glass strands to a specific length.

Applications are as diverse as friction breaks, paper reinforcement, Gypsum reinforcement, veil.

SPECIFICATIONS

| Reference | Coupling agent | Diameter (µm) | Fiber Length (mm) | Loss of ignition (%) | Moiture content (%) | Alcali content (%) |

|---|---|---|---|---|---|---|

| TGFS 423/ 10 | Silane | 10 | 4.0 / 6.4 / 12.7 | 0.10 +/- 0.05 | 6.0 +/- 2.0 | <0.8 |

| TGFS 423/ 13 | Silane | 13 | 4.0 / 6.4 / 12.7 | 0.10 +/- 0.05 | 6.0 +/- 2.0 | <0.8 |

| TGFS 423/ 16 | Silane | 16 | 4.0 / 6.4 / 12.7 | 0.10 +/- 0.05 | 6.0 +/- 2.0 | <0.8 |

PACKAGING

TGI’s chopped strands are packed as follow:

– Individual cartons of 20 kg (50 units per pallet)

– Big Bags of 1,000 kg

STORAGE

TGI’s Wet chop 423 should be stored indoors in a dry location. The product should remain in its original packaging, preferably closed until just prior to use. The temperature should not exceed 35°C and the relative humidity should be kept below 70 %.

FRP Services Europe reserves the right to change the information given herein without prior notice. We believe this information to be reliable but we do not guarantee its applicability to the user’s process or assume liability for occurrence arising out of its use. The user, by accepting Products described herein, agrees to be responsible for thoroughly testing any application before committing to production. March 2006

E GLASS MARBLES

E Glass marbles are manufactured for the production of glass fiber reinforcement.

1 CHEMICAL PROPERTIES OF E-GLASS (%)

| Components | Value | Tolerances |

| SiO2 | 54.10 | ±0.5 |

| Al2O3 | 14.60 | ±0.4 |

| CaO | 16.60 | ±0.3 |

| B203 | 8.80 | ±0.5 |

| MgO | 4.60 | ±0.3 |

| Na2O + K2O | < 0.7 | |

| Fe2O3 | < 0.5 | |

| R2O | < 0.8 |

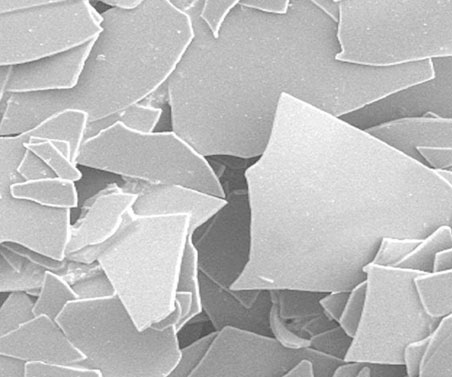

MILLED FIBER

PROPERTIES

Microglass are E-glass filaments hammer milled to various bulk densities.

These products are used as a filler/reinforcement in composites to increase mechanical properties (tensile, flexural, impact) and minimize distorsion at elevated temperatures, improve dimensional stability.

SPECIFICATIONS

| Ref. | Screen Size (inches) | Average Fiber Diameter (microns) | Average Fiber length (microns) | Loose Bulk Density (g/cc) | Moisture Content (%) | Sizing | Appearance |

|---|---|---|---|---|---|---|---|

| 3082 | 1/32 | 16 | 120 | 1.050 | <0.1 | Unsized | Powdery |

| 3080 | 1/32 | 16 | 150 | 0.925 | <0.1 | Unsized | Powdery |

| 3032 | 1/32 | 16 | 200 | 0.775 | <0.1 | Unsized | Powdery |

| 3016 | 1/16 | 10 | 140 | 0.525 | <0.1 | Unsized | Floccular |

| 3004 | 1/4 | 10 | 210 | 0.375 | <0.1 | Unsized | Floccular |

| 6608 | 1/8 | 16 | 470 | 0.275 | <0.1 | Direct Mill | Floccular |

| 6616 | 1/16 | 16 | 290 | 0.425 | <0.1 | Direct Mill | Floccular |

| 7280 | 1/32 | 16 | 120 | 0.925 | <0.1 | Cationic | Powdery |

| 7232 | 1/32 | 16 | 230 | 0.775 | <0.1 | Cationic | Powdery |

| 7216 | 1/16 | 10 | 170 | 0.525 | <0.1 | Cationic | Floccular |

| 7204 | 1/4 | 10 | 230 | 0.375 | <0.1 | Cationic | Floccular |

| EB120 30W | 120 | 0.36 | 38 | 15 | 20 | 15 | 2.80 |

| 9110 | 1/32 | 16 | 150 | 0.925 | <0.1 | Silane | Powdery |

| 9132 | 1/32 | 16 | 220 | 0.775 | <0.1 | Silane | Powdery |

| 9007D | 1/16 | 10 | 150 | 0.525 | <0.1 | Silane | Floccular |

| 9114 | 1/4 | 10 | 160 | 0.375 | <0.1 | Silane | Floccular |

• 3000 Series = Untreated fibers compatible with all thermoset and thermoplastic resins

• 6000 Series = Low cost fibers with higher levels of surface treatment compatible with all thermoset and thermoplsatic resins

• 7000 Series = Cationic surface treatment to accelerate wet out, improve dispersion, and overall processability. Compatible with all thermoset and thermoplastic resins

• 9000 Series = Silane surface treated fibers for improved bonding between the inorganic glass and the organic resin. Sizings are available for Polyesters, epoxies, phenolics, polyurethanes, polyvinyl chloride and other resin systems

NEEDLE MAT

APPLICATIONS

• This product has been designed for a wide range of processes, such as hand lay up, Pultrusion, winding, GMT, RTM, …

• Recommended for FRP products, such as shipbuilding industry, automotive, leisure industry,

SPECIFICATIONS

| Product | Needle combination mat | ||

|---|---|---|---|

| Mass (g/m2) | 600±20 | ||

| Thickness(mm) | 0.78 | ||

| Structure | needle | Sizing | Silane |

| FABRIC | YARN (TEX) | Warp | 66tex×4×2 |

| weft | 66tex×3×2 | ||

| Density(ends/cm) | Warp | 3.6 | |

| Weft | 2.8 | ||

| Mass (g/m2) | 300 | ||

| Chopped strand yarn | Mass (g/m2) | 300 | |

| Tensile Strength (N/50mm) | Warp | 900 | |

| Weft | 450 | ||

STORAGE

FRP’s Powder Mats should be stored dry in their original packaging (contracted PE foil and cardboard box). Storage temperature : between 10 and + 35 °C – Relative humidity : between 35 and 85 %.

FRP Services Europe reserves the right to change the information given herein without prior notice. We believe this information to be reliable, but do not guarantee its applicability to the user’s process or assume liability for occurrence arising out of its use. The user, by accepting products described herein

agrees to be responsible for thoroughly testing any application before committing to production. MAY 2005

NE Glass

T Glass

3D space fabrics

REINFORCEMENT SCRIM : Please refer to our Industrial textiles section

For more information, please contact us by filling out below form

Get a cost estimate

Please submit a detailed outline of your business requirement so that our team of experts could get in touch with you with a customised product/service cost estimate within the next 48 hours.

Featured Products

Composites

FRP Services & Company offices in 18+ cities in 12+ countries

Global Network

HEADQUARTERS

- FRP SERVICES & COMPANY

FRP bldg.,

1-15-9 Awaza,

Nishi-ku, Osaka

Japan 550-0011 - +81 (6) 6535-1933

- inquiry@frpservices.com

REGIONAL OFFICE

- FRP SERVICES & COMPANY

KDX Nihonbashi Edo-dori Bldg,

8F 3-9-4, Nihonbashi-honcho, Chuo-ku,

Tokyo Japan 103-0023 - +81 (0) 3 5643 8061

- inquiry@frpservices.com

INDIA

- FRP SERVICES & CO INDIA PVT LTD,

F 104, Ascot Centre,

Sahar Airport Road,

Andheri - East, Mumbai

India 400099 - +91-22-28351401

- inquiry@frpservices.com

SRI LANKA

PAKISTAN

- FRP SERVICES & COMPANY (P.L.O)

Business Arcade,

3rd Floor, Suit# 309,

Shahrah-e-Faisal, Karachi

Pakistan 75400 - +92 (21) 3432 7632

- inquiry@frpservices.com

PHILIPPINES

- TY COMPOSITE INTERNATIONAL CORPORATION

National Highway Teco Industrial Park,

Brgy. Bundagul, Mabalacat City,

Pampanga 2010

Philippines - +63-45-403-9914

- inquiry@frpservices.com

VIETNAM

HANOI REPRESENTATIVE OFFICE

- FRP SERVICES & COMPANY

Room 402,04th floor,

Vinahud Building, Trung Yen 9 road,

Cau Giay District, Hanoi,

Vietnam. - +84 (24) 3728 2357

- inquiry@frpservices.com

VIETNAM

HO CHI MINH OFFICE

- FRP SERVICES & COMPANY

CSI Business Centre,

Room 202, 2th Floor,

Ben Thanh Building

70 Ly Tu Trong Str, Ben Thanh Ward,

District 1,Ho Chi Minh City,

Vietnam - +84 (28) 3827 2199

- inquiry@frpservices.com

TAIWAN

- TAIPEI REPRESENTATIVE OFFICE

7F-9, No. 207, Tung-Hwa

North Road, Taipei,

Taiwan - +886 (2) 2713 3111

- inquiry@frpservices.com

SINGAPORE

- FRP SERVICES (ASIA) PTE LTD.

24 Raffles Place #17-04A

Clifford Centre

Singapore 048621 - +65 6270 5001

- inquiry@frpservices.com

CHINA

- FRP SERVICES & CO. SHANGHAI OFFICE

Shanghai International Trade Center,

25 #2508, 2201 Yan An Road (West),

Shanghai 200336,

China - +86-21-6209-5907

- inquiry@frpservices.com

FRANCE

- FRP SERVICES EUROPE SARL

Square de l’Arbois Bât.

B3 565 Rue René Descartes,

13857 Aix-en-Provence Cédex3,

France - +33 (0) 4 4297 5910

- inquiry@frpservices.com

UAE - DUBAI

- FRP SERVICES & COMPANY MIDDLE EAST (BRANCH)

4WA, 628, Dubai Airport Free Zone,

Dubai,

UAE - +971 (4) 204 5050

- inquiry@frpservices.com

NORTH AMERICA - USA

REGIONAL HEADQUARTERS

- FRP SERVICES & CO. (AMERICA) INC.

535 Fifth Avenue,

Suite 1008, New York,

NY 10017,

U.S.A - +1 (212) 695 8000

- +1 (212) 695 3100

- inquiry@frpservices.com

NORTH AMERICA – CANADA

REGIONAL BRANCH OFFICE

SOUTH AMERICA

BRAZIL REP OFFICE

- FRP SERVICES & CO. (AMERICA) INC.

Avenida Pompeia,

634 - Suite 501, Vila Pompeia,

São Paulo, CEP 05022-000

Brazil - +55 (11) 3589 5749

- +55 (11) 3589 5709

- inquiry@frpservices.com

Meet Us

Contact

Composites Division

Address: FRP SERVICES & COMPANY

Yoshihashi Building 2F,

13-10, Nihonbashi-Kobunacho,

Chuo-ku, Tokyo,

103-0024, Japan

Telephone: +81 (6) 6535-1936

Fax: +81 (6) 6535-1677

Website: www.frpservices.com

Email: inquiry@frpservices.com