Carbomer

Product Name: Carbomer

Application: Sanitizers

CAS No:

HS No:

FRP Refer:

Description: Carbomers function as thickening, dispersing, suspending and emulsifying agents in cosmetics and personal care products. They are widely used to provide emulsion stability.

AQUPEC HV-701EDR

INCI Name: Acrylates/C10-30 Alkylacrylate Crosspolymer

Introduction

AQUPEC HV-701EDR is the traditional Sumitomo Seika

product which has been specially designed to disperse

easily. Additionally, AQUPEC HV-701EDR is produced in

soft solvents (Class 2 of ICH guide, Benzene free).*

*ICH Guideline for Registration of Pharmaceuticals

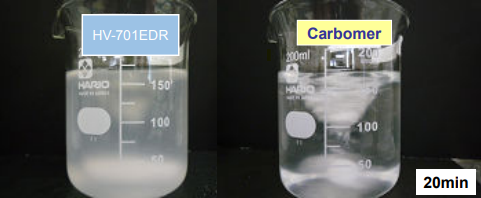

Figure 1: Comparison between dispersion of HV-701EDR

and Carbomer

As Figure 1 shows, dispersion of HV-701EDR is

significantly much faster than that of carbomer. After 20 min

stirring, HV-701EDR is fully dispersed while dispersion of

carbomer needs some more time to be complete.

Chemical and physical characteristics:

* Not to be used as specification

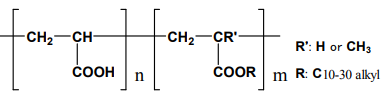

| Chemical | Acrylates/C10-30 Alkylacrylate |

| Name | Crosspolymer |

| CAS No. | Confidential |

| Chemical |  |

| Structure | |

| INCI name | Acrylates/C10-30 Alkylacrylate

Crosspolymer |

| Appearance | White Powder |

| Bulk density | 0.18-0.22g/ml |

| pH(0.5 % aqueous) a) |

Aprox 3 |

| Solvent type | Class 2 (Benzene free) |

a) Before neutralization

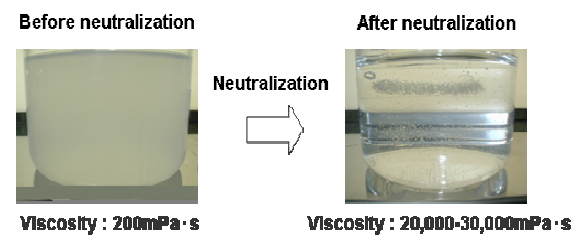

Figure 2: Neutralization of AQUPEC HV-701EDR

AQUPEC HV-701EDR is Acrylates/C10-30 Alkylacrylate

Crosspolymer. AQUPEC HV-701EDR in water (before

DISCLAIMER

(1) This brochure (and the information contained herein) is provided solely for promotional and illustrative purposes only and is not nor

intended to constitute any promise, representation or any kind of warranty as to any product or any other matter. The information in this

brochure is subject to change without notice and is not intended to be relied upon.

(2) All representations and warranties relating to products are set out exhaustively in the relevant contract of sale or service, and nothing

in this brochure shall be construed as adding to or altering any term of such contract.

(3) Please refer all enquiries concerning any product or this brochure to SUMITOMO SEIKA CHEMICALS CO., LTD.

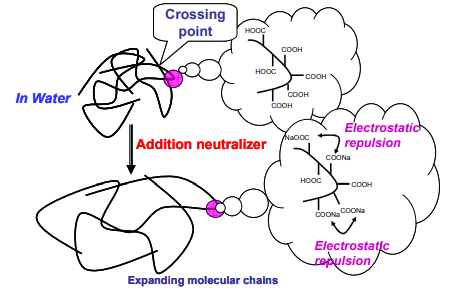

neutralization) is an acid (pH approx 3) cloudy dispersion (Figure 2). In this state, AQUPEC’s chains are tangled giving a low viscous medium. During neutralization, acid moities of AQUPEC are neutralized. The resulting acrylate groups repulse each other expanding AQUPEC’s chains (Figure 3). The result is a high viscous clear gel (Figure 2). On the other hand, as polymer chain contains some hydrophobic groups, good emulsion can be obtained. That fact makes the applicability of this polymer wider.

Figure 3: Mechanism of thickening of AQUPEC

Specifications

Table 1. Properties of AQUPEC HV-701EDR.

| Item | HV-701EDR |

| 1wt% mucilagea) | 30,000 – 45,000 (pH7.0-7.8, Spindle #6) |

| 1 wt% mucilage + 1.0 wt% salt a) |

4,000 – 10,000 (pH7.0-7.8, Spindle #5) |

a) Viscosity[mPas] (BH Type Viscometer, 20rpm).

Key benefits:

• Easy dispersion.

• Benzene free.

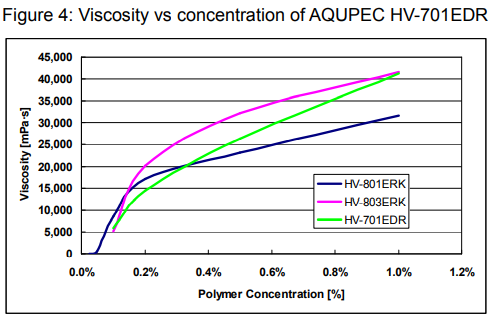

• High viscosity at low concentration (Figure 4).

Features.

Basic Polymer Properties in Water.

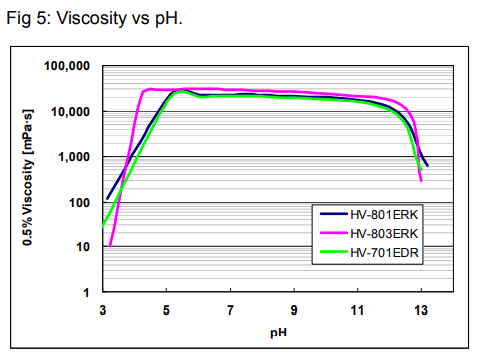

1) Effect of pH.

Excellent thickening effect is achieved in the range of pH 5 to 11 (Figure 5). Out of this range, a decrease in viscosity occurs due to high ionic strength.

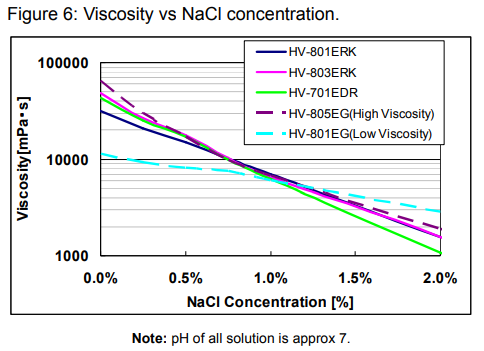

2) Effect of electrolytes

General speaking, anionic thickeners (such as AQUPEC) behavior in solution is significantly affected by the ionic strength. When electrolytes (such as sodium chloride) are present thickening capacity of AQUPEC lowers. The result is a decrease in viscosity of the aqueous solution (Figure 6).

surfactant) may lead to the flocculation of AQUPEC.

Storage & Handling

AQUPEC HV-701EDR is very hygroscopic and swells quickly in the presence of water. Keep the container closed when not in use, and store in a dry and dark area.

Packing

15 kg box

Shelf life

Two years from the date of the initial analysis (except for “loss on drying”)

Recommendations for addition of HV-701EDR

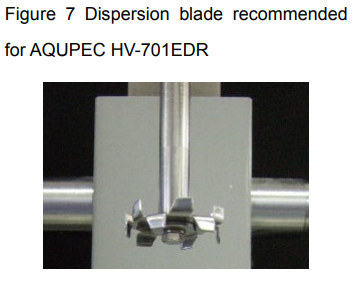

- Add AQUPEC HV-701EDR gradually to water or mixtures which contain more than 80% water (With stirring). A common stirring blade can be used, but a dispersion blade (Figure 7) is recommended.

- Add AQUPEC HV-701EDR with stirring.

- After AQUPEC HV-701EDR is dispersed uniformly, the addition of the proper neutralizer will give a gel. Other ingredients can be added as well to complete the formulation.

- Before neutralization, the addition of some compounds which act as electrolytes (such as anionic surfactant) may lead to the flocculation of AQUPEC.

Suggested Applications.

AQUPEC HV-701EDR can be used for a wide range of

applications. For ex:

- Moisturizing Cream

- Shampoo

Viscosity Measurement Procedure

1. Using a graduated cylinder, measure 400 mL of distille water (previously maintained at 25oC), and pour into a clean dry 1000-mL beaker.

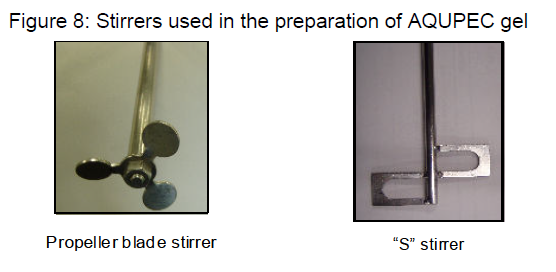

2. Set up a variable speed laboratory stirrer with a propeller blade and adjust the speed to 1000 ± 50 rpm.

3. Weigh AQUPEC (5 g for a 1 % solution).

4. Add slowly the polymer with stirring (approx 1000 rpm). When addition of polymer is finished, add 100 mL water in the beaker, and stir for 30 minutes.

5. Remove the propeller blade from beaker, and cover with watch glass or aluminum foil. Keep the solution in a water bath at 25 oC until foam breaks and there are not bubbles on the surface of the solution.

6. Place the “S” stirrer in the solution (Figure 8). Using a 10-mL graduated pipette quickly add the corresponding neutralizing agent.

7. Stir the gel formed at 220-250 rpm for one hour.

8. Check the pH of the gel with a pH meter. Values should be between 7.0-7.8. If solution is still acid, add some amount of NaOH solution 18 wt %. If it is too basic, discard it and prepare a new one.

9. For electrolyte resistance test: Add 5 g of NaCl (solution will be 1 wt % NaCl).

10. Check the temperature of the gel by placing a thermometer straight down into the center of the gel. Do not stir or incorporate any air into the gel, as it must be as free of air as possible. Leave in water bath until temperature becomes between 24.5 and 25.5oC.

11. Measure the viscosity of the gel with VISMETRON at 20 rpm using suitable spindle.

Formulations:

Moisturizing cream

| Moisturizing Cream | ||||

| PART A | ||||

| Cetyl Alcohol | 1.0 % | |||

| Caprylic/Capric Triglyceride | 10.3 % | |||

| Isopropyl Myrystate | 4.0 % | |||

| PART B | ||||

| Water | 74.3 % | |||

| Glycerin | 5.0 % | |||

| AQUPEC HV-701EDR | 0.2 % | |||

| Polysorbate 60 | 1.0 % | |||

| PART C | ||||

| 6% NaOH | 2.2 % | |||

| PART D | ||||

| Ethanol | 6.0 % | |||

| 100.0 % | ||||

Procedure

1. PART A: Mix PHASE A ingredients (bath at 75℃) .

2. PART B: In a separated beaker, mix Glycerin and Polysorbate 60 in water. Add AQUPEC HV-701EDR to that solution and disperse keeping temperature at 75℃.

3. Mix PART A and PART B (bath temperature = 75℃), with stirring.

4. Keep stirring while add the corresponding amount of 6% NaOH aqueous solution (PHASE C).

5. Cool mixture down (about 25℃).

6. When batch temperature becomes about 25℃, add PART D and stir.

Shampoo.

| Shampoo | ||||

| PART A | ||||

| AQUPEC HV-701EDR | 0.2 % | |||

| Water | 16.0 % | |||

| PART B | ||||

| Sodium Laureth Sulfate (3mon, 25%) | 44.0 % | |||

| Potassium hydroxide (5%) | 9.5 % | |||

| Water | 9.5 % | |||

| PART C | ||||

| Sodium Benzoate | 0.3 % | |||

| Disodium EDTA | 0.1 % | |||

| Water | 6.0 % | |||

| PART D | ||||

| Cocamidopropyl Betaine (30%) | 21.3 % | |||

| PART E | ||||

| Ceric Acid | 0.4 % | |||

| 100.0 % | ||||

Procedure

1. PHASE A: Disperse AQUPEC HV-701EDR in water. Warm it up to 60℃.

2. PHASE B: In a separated beaker, mix PHASE B ingredient.

3. Add PHASE B to PHASE A. Mix it 5 minutes keeping temperature at 60℃.

4. PHASE C: In a separated beaker, dissolve sodium benzoate and disodium EDTA in water.

5. Add PHASE C to the mixture, and mix it 5 minutes at 60℃.

6. Add PHASE E and mix it 5 minutes at 60℃.

7. After cooling down below 40℃, add PHASE E and stir.

Alcohol gel

| Alcohol gel | ||||

| AQUPEC HV-701EDR | 0.5 % | |||

| Ethanol | 70.0 % | |||

| PART B | ||||

| Water | 29.0 % | |||

| Diisopropanolamine | 0.5 % | |||

| 100.0 % | ||||

Procedure

1. Mix ethanol and water.

2. Disperse AQUPEC HV-701EDR, and stir it for about 5 hours.

3. Add diisopropylamine and stir.

For more information, please contact us by filling out below form

Get a cost estimate

Please submit a detailed outline of your business requirement so that our team of experts could get in touch with you with a customised product/service cost estimate within the next 48 hours.

Featured Products

Chemicals

FRP Services & Company offices in 18+ cities in 12+ countries

Global Network

HEADQUARTERS

- FRP SERVICES & COMPANY

FRP bldg.,

1-15-9 Awaza,

Nishi-ku, Osaka

Japan 550-0011 - +81 (6) 6535-1933

- inquiry@frpservices.com

REGIONAL OFFICE

- FRP SERVICES & COMPANY

KDX Nihonbashi Edo-dori Bldg,

8F 3-9-4, Nihonbashi-honcho, Chuo-ku,

Tokyo Japan 103-0023 - +81 (0) 3 5643 8061

- inquiry@frpservices.com

INDIA

- FRP SERVICES & CO INDIA PVT LTD,

F 104, Ascot Centre,

Sahar Airport Road,

Andheri - East, Mumbai

India 400099 - +91-22-28351401

- inquiry@frpservices.com

SRI LANKA

PAKISTAN

- FRP SERVICES & COMPANY (P.L.O)

Business Arcade,

3rd Floor, Suit# 309,

Shahrah-e-Faisal, Karachi

Pakistan 75400 - +92 (21) 3432 7632

- inquiry@frpservices.com

PHILIPPINES

- TY COMPOSITE INTERNATIONAL CORPORATION

National Highway Teco Industrial Park,

Brgy. Bundagul, Mabalacat City,

Pampanga 2010

Philippines - +63-45-403-9914

- inquiry@frpservices.com

VIETNAM

HANOI REPRESENTATIVE OFFICE

- FRP SERVICES & COMPANY

Room 402,04th floor,

Vinahud Building, Trung Yen 9 road,

Cau Giay District, Hanoi,

Vietnam. - +84 (24) 3728 2357

- inquiry@frpservices.com

VIETNAM

HO CHI MINH OFFICE

- FRP SERVICES & COMPANY

CSI Business Centre,

Room 202, 2th Floor,

Ben Thanh Building

70 Ly Tu Trong Str, Ben Thanh Ward,

District 1,Ho Chi Minh City,

Vietnam - +84 (28) 3827 2199

- inquiry@frpservices.com

TAIWAN

- TAIPEI REPRESENTATIVE OFFICE

7F-9, No. 207, Tung-Hwa

North Road, Taipei,

Taiwan - +886 (2) 2713 3111

- inquiry@frpservices.com

SINGAPORE

- FRP SERVICES (ASIA) PTE LTD.

24 Raffles Place #17-04A

Clifford Centre

Singapore 048621 - +65 6270 5001

- inquiry@frpservices.com

CHINA

- FRP SERVICES & CO. SHANGHAI OFFICE

Shanghai International Trade Center,

25 #2508, 2201 Yan An Road (West),

Shanghai 200336,

China - +86-21-6209-5907

- inquiry@frpservices.com

FRANCE

- FRP SERVICES EUROPE SARL

Square de l’Arbois Bât.

B3 565 Rue René Descartes,

13857 Aix-en-Provence Cédex3,

France - +33 (0) 4 4297 5910

- inquiry@frpservices.com

UAE - DUBAI

- FRP SERVICES & COMPANY MIDDLE EAST (BRANCH)

4WA, 628, Dubai Airport Free Zone,

Dubai,

UAE - +971 (4) 204 5050

- inquiry@frpservices.com

NORTH AMERICA - USA

REGIONAL HEADQUARTERS

- FRP SERVICES & CO. (AMERICA) INC.

535 Fifth Avenue,

Suite 1008, New York,

NY 10017,

U.S.A - +1 (212) 695 8000

- +1 (212) 695 3100

- inquiry@frpservices.com

NORTH AMERICA – CANADA

REGIONAL BRANCH OFFICE

SOUTH AMERICA

BRAZIL REP OFFICE

- FRP SERVICES & CO. (AMERICA) INC.

Avenida Pompeia,

634 - Suite 501, Vila Pompeia,

São Paulo, CEP 05022-000

Brazil - +55 (11) 3589 5749

- +55 (11) 3589 5709

- inquiry@frpservices.com

Meet Us

Contact

Chemicals Division

Address: FRP SERVICES & COMPANY

Yoshihashi Building 2F,

13-10, Nihonbashi-Kobunacho,

Chuo-ku, Tokyo,

103-0024, Japan

Telephone: +81 (0) 3 5643 8061

Fax: +81 (0) 3 5634 8064

Website: www.frpservices.com

Email: inquiry@frpservices.com