Fillers & Admixtures

Calcium Carbonate (Filler)

Aluminium Hydroxide (for Fire Retardant agent)

Thixotropic agents : Fumed silica (Reolosil), Tokusil, Finesil

Magnesium Oxide

Talc

Antimony Trioxide

Iron Oxide

Clay

Glass Powder

Glass Beads

Wollastonite

Fumed Silica

Sales specifications

| Grade | QS-09 | QS-10 QS-10LS |

QS-102 | CP 102 | QS-20 QS-20LS |

QS-30 | QS-30C | QS-40 |

|---|---|---|---|---|---|---|---|---|

| Appearance | White powder | |||||||

| BET surface area (m²/g) | 90+/-20 | 140+/-20 | 200+/-20 | 200+/-20 | 220+/- 20 | 300+/-30 | 300+/- 30 | 380 +/-30 |

| Primary particle (m/m) | 22 | 15 | 12 | 12 | 12 | 7 | 7 | 7 |

| Bulk density (g/L) | 50 | 50 40 |

50 | 100 | 50 40 |

50 | 100 | 50 |

| Moisture content(Dry up, %) | <1.5 | <1.0 | <1.5 | <1.5 | <1.5 | <2.0 | <2.0 | <2.0 |

| Ph(4% suspension) | 4.2 | 4.2 | 4.2 | 4.2 | 4.2 | 4.2 | 4.2 | 4.2 |

| SiO²(%) | >99.9 | >99.9 | >99.9 | >99.9 | >99.9 | >99.9 | >99.9 | >99.9 |

| Cl (ppm) | <50 | <50 | <50 | <50 | <50 | <50 | <50 | <50 |

| Fe(ppm) | <20 | <20 | <20 | <20 | <20 | <20 | <20 | <20 |

| Al(ppm) | <20 | <20 | <20 | <20 | <20 | <20 | <20 | <20 |

| 44um residue (%) | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 |

| Packaging (kg) | 10 | 10 | 10 | 15 | 10 | 10 | 15 | 10 |

Hydroxypropil Methylcellulose

ShinEtsu

TYPE OF POLYMER

Hydroxypropyl Methylcellulose

1.Methyloxirane: REACH No.: 01-2119480483-35 :

2.Chlomethane: pre registration REACH No :05-2114650762-47 ( registration expected in 2013)

SPECIFICATIONS

| Reference | Methoxyl content (%) | Hydroxypropoxyl content (%) | Moisture (%) | Ash content (Na2SO4) (%) | Viscosity range (2%, 20°C) mPa |

|---|---|---|---|---|---|

| METOLOSE 90SH - 15000 | 19 - 24 | '4 - 12 | max. 5.0 | max. 1.0 | 12,000 - 18,000 |

PACKAGING

METOLOSE 90SH-15000 is supplied in 4 plies paper bag (including three outside layers of craft paper and one internal layer of polyethylene film), each containing 20 kg net.

STORAGE

METOLOSE 90SH-15000 should be stored dry in its original packaging.

Storage temperature : max. 35 °C – Relative moisture : < 70 %

FRP Services Europe reserves the right to change the information given herein without prior notice. We believe this information to be reliable, but do not guarantee its applicability to the user’s process or assume liability for occurrence arising out of its use. The user, by accepting products described herein agrees to be responsible for thoroughly testing any application before committing to production. March 2007

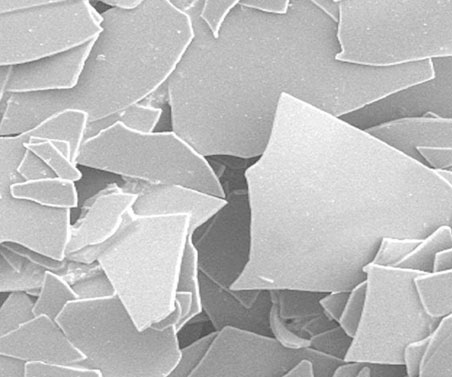

WOLLASTONITE

PROPERTIES

Wollastonites are acicular mineral products milled to various morphologies and bulk densities. These products can be surface treated to enhance performance in thermoset and thermoplastic resins.

They increase mechanical properties (tensile, flexural, impact) and minimize distorsion at elevated temperatures, improve dimensional stability and provide low moisture absorption.

| Component | Weight % |

|---|---|

| CaO | 46.70 |

| SiO2 | 52.20 |

| Fe2O3 | 0.15 |

| Al2O3 | 0.25 |

| MgO | 0.20 |

| Loss of Ignition | 0.50 |

SPECIFICATIONS

| Ref. | Average Diameter (microns) | Average Aspect Ratio | Loose Bulk Density (g/cc) | Tapped Bulk (g/cc) | Appearance |

|---|---|---|---|---|---|

| 400U | 4.5 | 7.5 | 0.65 | 0.90 | Powder |

| 400S | 4.5 | 7.5 | 0.67 | 0.95 | Powder |

| 400H | 4.5 | 7.5 | 0.69 | 1.00 | Powder |

| 520U | 5 | 20 | 0.25 | 0.43 | Fiber |

| 520S | 5 | 20 | 0.32 | 0.50 | Fiber |

| 520H | 5 | 20 | 0.37 | 0.59 | Fiber |

| 720U | 5.5 | 20 | 0.32 | 0.60 | Fiber |

| 720S | properties to be determined | ||||

| 720H | 5.5 | 20 | 0.38 | 0.57 | Fiber |

| 800U | 3 | 9 | 0.46 | 0.65 | Powder |

| 800S | 3 | 9 | 0.49 | 0.66 | Powder |

| 800H | 3 | 9 | 0.61 | 0.81 | Powder |

| 905U | 9 | 5 | 0.72 | 1.10 | Powder |

| 905S | 9 | 5 | 0.76 | 1.08 | Powder |

| 905H | pproperties to be determined | ||||

| 915U | 9 | 15 | 0.50 | 0.83 | Fiber |

| 915S | 9 | 15 | 0.50 | 0.85 | Fiber |

| 915H | 9 | 15 | 0.67 | 0.96 | Fiber |

| 1515U | 15 | 15 | 0.66 | 1.15 | Fiber |

| 1515S | 15 | 15 | 0.58 | 0.97 | Fiber |

| 1515H | pproperties to be determined | ||||

GLASS BEADS

PROPERTIES

YWGB09# Series

Sandblasting glass bead is powered by compressed air to spray glass beads onto the surface of workpiece with high speed and high pressure for shot peening and polishing processing,

It’s mainly used for cleaning all kinds of molds such as punching, forging glass , rubber, plastic,metal casting,extrusion,etc.It can eliminate tensile stress,increase fatigue life and improve wear resistance Normally its hardness ≥5.5density 2.4-2.6g/cm³.

We supply the sandblasting glass bead as per American standard

MIL-G-9954A.

Applications

1. Semi-luster surface treatment on stainless steel products.

2. Clean and polish moulds for punching, forging, metal casting, glass products,rubber products and others.

3. Eliminate all kinds of machine parts tensile stress ,increase fagitue life and improve wear resistance.For instance, alrcraft engine turbine,blade,axis,undercarriage,as well as all kinds of spring,gear hydraulic parts,etc.

4. Clean semiconductor device and plastic sealed pair pipe before plating tin and remove edge and burrs.

5. Remove blockage in piston and cylinder.

6. Clean coil,brush,rotor and other spare parts when the motor and generator are overhauled.

7. Clean and deburr various metal pipes and nonferrous metal precise casting Shotblastingenhancement and polishina from textile machinery components.

8. Provide bright and sub glossy surface for medical apparatus instruments and automobile spare parts.

| Item | Mesh | Diameter (micron) |

|---|---|---|

| YWGB01# | 14-20 | 1400-850 |

| YWGB02# | 52.20 | 52.20 |

| YWGB03# | 20-30 | 850-600 |

| YWGB04# | 30-40 | 600-425 |

| YWGB05# | 40-50 | 425-300 |

| YWGB06# | 50-70 | 300-212 |

| YWGB07# | 60-80 | 250-180 |

| YWGB08# | 212-150 | 0.50 |

| YWGB09# | 90-150 | 180-125 |

| YWGB10# | 100-170 | 150-90 |

| YWGB11# | 120-200 | 125-75 |

| YWGB12# | 140-230 | 106-63 |

| YWGB13# | 170-325 | 90-45 |

PRODUCT DATA

| Size (Diameter) | Between 0 and 800 um (see table Standard Sizes) |

| Transformation temperature | 549°C |

| Softening point (Littleton point) | 734°C |

| Melting point | 1446°C |

| Specific thermal Conductivity | 1.129 W/(mK) |

| Thermal expansion | 9.05 10-6 K1 120 °C1 (Coefficient of linear expansion α) |

| Specific thermal capatcity | 1.329 kj/kg K [>600 °C] |

| Youngs-Module | 63 GPa |

| Hardness according to Mohs | ≥6 |

| Specific gravity(g/cm3) | 2.4-2.6 |

| Refractive index | ≥1.5 |

| Spherical beads (%) | ≥80 |

| Arsenic | <=200ppm |

| Lead | <=200ppm |

| Antimony | <=200ppm |

PACKAGING

Packages just like the photo in right and the details are 25kgs/bag, 40bags/pallet, 20pallets per 20 feet container.

FRP Services Europe reserve the right to change the information given herein without prior notice. We believe this information to be reliable But we do not guarantee its applicability to the user’s process or assume liability for occurrence arising out of its use. The user, by accepting Products described herein, agrees to be responsible for thoroughly testing any application before committing to production.

For more information, please contact us by filling out below form

Get a cost estimate

Please submit a detailed outline of your business requirement so that our team of experts could get in touch with you with a customised product/service cost estimate within the next 48 hours.

Featured Products

Composites

FRP Services & Company offices in 18+ cities in 12+ countries

Global Network

HEADQUARTERS

- FRP SERVICES & COMPANY FRP bldg., 1-15-9 Awaza, Nishi-ku, Osaka Japan 550-0011

- +81 (6) 6535-1933

- inquiry@frpservices.com

REGIONAL OFFICE

- FRP SERVICES & COMPANY KDX Nihonbashi Edo-dori Bldg, 8F 3-9-4, Nihonbashi-honcho, Chuo-ku, Tokyo Japan 103-0023

- +81 (0) 3 5643 8061

- inquiry@frpservices.com

INDIA

- FRP SERVICES & CO INDIA PVT LTD, F 104, Ascot Centre, Sahar Airport Road, Andheri - East, Mumbai India 400099

- +91-22-28351401

- inquiry@frpservices.com

SRI LANKA

PAKISTAN

- FRP SERVICES & COMPANY (P.L.O) Business Arcade, 3rd Floor, Suit# 309, Shahrah-e-Faisal, Karachi Pakistan 75400

- +92 (21) 3432 7632

- inquiry@frpservices.com

PHILIPPINES

- TY COMPOSITE INTERNATIONAL CORPORATION National Highway Teco Industrial Park, Brgy. Bundagul, Mabalacat City, Pampanga 2010 Philippines

- +63-45-403-9914

- inquiry@frpservices.com

VIETNAM

HANOI REPRESENTATIVE OFFICE

- FRP SERVICES & COMPANY Room 402,04th floor, Vinahud Building, Trung Yen 9 road, Cau Giay District, Hanoi, Vietnam.

- +84 (24) 3728 2357

- inquiry@frpservices.com

VIETNAM

HO CHI MINH OFFICE

- FRP SERVICES & COMPANY CSI Business Centre, Room 202, 2th Floor, Ben Thanh Building 70 Ly Tu Trong Str, Ben Thanh Ward, District 1,Ho Chi Minh City, Vietnam

- +84 (28) 3827 2199

- inquiry@frpservices.com

TAIWAN

- TAIPEI REPRESENTATIVE OFFICE 7F-9, No. 207, Tung-Hwa North Road, Taipei, Taiwan

- +886 (2) 2713 3111

- inquiry@frpservices.com

SINGAPORE

- FRP SERVICES (ASIA) PTE LTD. 24 Raffles Place #17-04A Clifford Centre Singapore 048621

- +65 6270 5001

- inquiry@frpservices.com

CHINA

- FRP SERVICES & CO. SHANGHAI OFFICE Shanghai International Trade Center, 25 #2508, 2201 Yan An Road (West), Shanghai 200336, China

- +86-21-6209-5907

- inquiry@frpservices.com

FRANCE

- FRP SERVICES EUROPE SARL Square de l’Arbois Bât. B3 565 Rue René Descartes, 13857 Aix-en-Provence Cédex3, France

- +33 (0) 4 4297 5910

- inquiry@frpservices.com

UAE - DUBAI

- FRP SERVICES & COMPANY MIDDLE EAST (BRANCH) 4WA, 628, Dubai Airport Free Zone, Dubai, UAE

- +971 (4) 204 5050

- inquiry@frpservices.com

NORTH AMERICA - USA

REGIONAL HEADQUARTERS

- FRP SERVICES & CO. (AMERICA) INC. 535 Fifth Avenue, Suite 1008, New York, NY 10017, U.S.A

- +1 (212) 695 8000

- +1 (212) 695 3100

- inquiry@frpservices.com

NORTH AMERICA – CANADA

REGIONAL BRANCH OFFICE

SOUTH AMERICA

BRAZIL REP OFFICE

- FRP SERVICES & CO. (AMERICA) INC. Avenida Pompeia, 634 - Suite 501, Vila Pompeia, São Paulo, CEP 05022-000 Brazil

- +55 (11) 3589 5749

- +55 (11) 3589 5709

- inquiry@frpservices.com

Meet Us

Contact

Composites Division

Address: FRP SERVICES & COMPANY

FRP BLDG, 1-15-9 AWAZA,NISHI-KU,

OSAKA 550-0011,

Japan

Telephone: +81 (6) 6535-1936

Fax: +81 (6) 6535-1677

Website: www.frpservices.com

Email: inquiry@frpservices.com